Legend

has it that Einstein once said “Everything should be made as simple

as possible, but not simpler”

In

truth, the quote isn’t actually Einstein’s, but he did agree with

it.

And

so do I, especially when it comes to jam cleats.

Years

ago, I became frustrated with the cam cleats and horn cleats that I used for my

halyards, roller furler, and centerboard lift. Cam cleats can all

too easily be released accidentally. Horn cleats take longer to tie off and usually require two

hands to make fast (unless you’re some sort of one-handed

horn-cleating ninja). They require too much attention for too

long when things get hectic.

What

I really wanted was a cleat that would hold a line fast by simply and

quickly wrapping one turn around it, using only one hand.

But

I also wanted the ability to secure the line to the cleat with no

possibility of it accidentally releasing.

And

I needed two sizes, but wanted the option to swap one size for the

other without having to drill more mounting holes.

I

also wanted something I could make myself because, well, that’s

what I do.

And

of course they had to be “as simple as possible, but no simpler”.

This

is what I came up with.

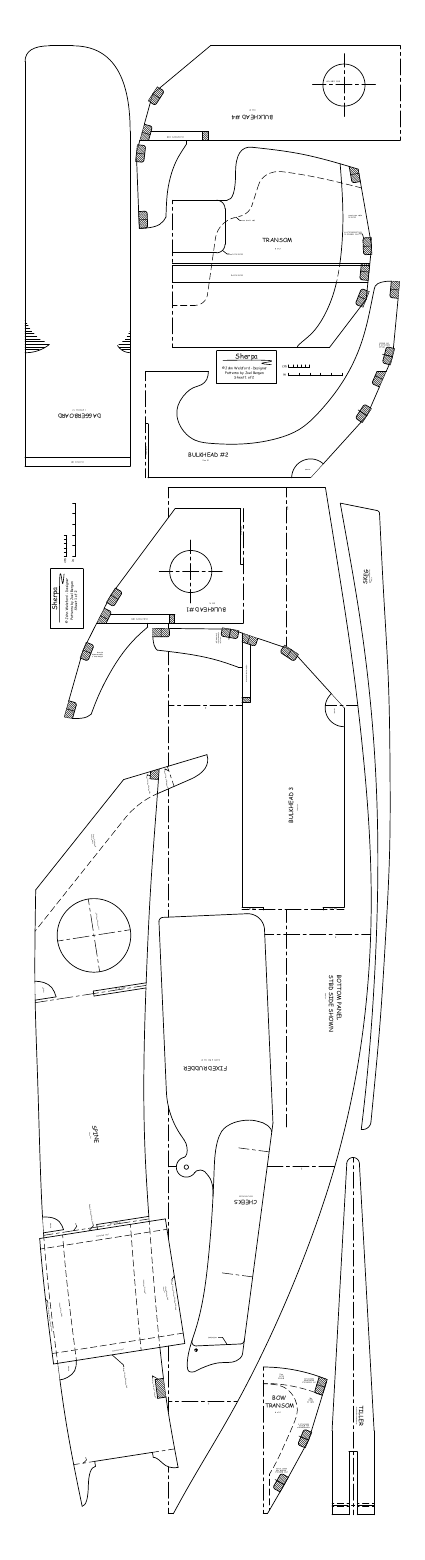

These

jam cleats are made from a scrap of 3/4” hardwood (1/2” for the

smaller cleat). I used white oak and painted them black. Pretty

much any type of hardwood and finish will do. For best results, use

a strong wood, with the grain running lengthwise, and a finish that’s

not too slippery. I suggest bare or oiled wood, painted rather than

varnished for example. Simply cut them out, round over all but the

bottom edges, drill two countersunk mounting holes and that’s it.

Here

are the cleats with a single turn around them. One wrap plus a tug to

jam the line under the horn is all it takes to make them hold

securely. I haven’t had an unintentional release yet.

For

ultimate security, add a hitch around the horn like this.

I

do both. When things are hectic, I do the one-handed wrap-and-tug.

After things settle down, I go back and add the hitch. Then I can

relax.

I made two variations of this jam cleat which I'll dub the Single Jammer and the Double Jammer.

With

the Single Jammer cleat, you route the line around the aft end of the cleat,

pull the line forward to tighten, then wrap around the forward end of

the cleat to secure.

I

prefer the Double Jammer cleat if the line already has a lot of tension on it.

Wrapping the line around the aft end of the cleat secures the line

instantly. Then, wrapping the line around the forward end of the cleat

secures the line even more.

I’ve

been using these cleats for several years now, and I absolutely love

them. Here are the plans if you would like to make some for

yourself. Download .zip